Search This Blog

Railway Axle Counter

Operation -

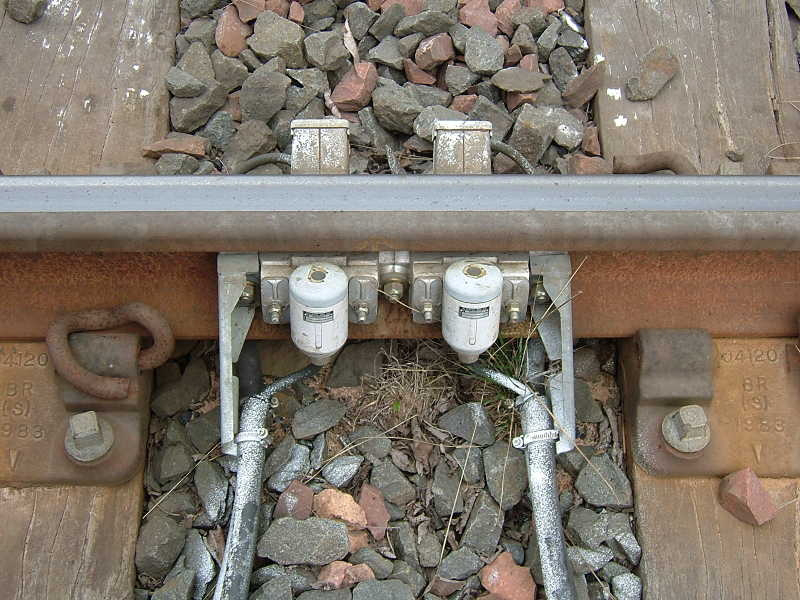

An axle counter consists of a sensor, which detects the individual axles of a train by mechanical, electrical or even fibre optic method, and an evaluator which counts the axles passing into and out of a rail section. The evaluator may also convert the analogue signal of the axle sensor into a digital signal. However, in some cases there is a separate unit which performs this task.

The system is set up by having an axle counter sensor installed at each end of a section. As each train axle passes the axle counter sensor at the start of the section, a counter increments. An axle counter sensor comprises two independent sensors (so the device can detect the direction and speed of a train by the order and time in which the sensors are passed). As the train passes a similar axle counter sensor at the end of the section, the system compares count at the end of the section with that recorded at the beginning. If the two counts are the same, the section is presumed to be clear.

This process is carried out by safety-critical centrally located computers, called "evaluators", with the axle counter sensors located at the required sites in the field. The axle counter sensors are either connected to the evaluator via dedicated copper cable or via a telecommunications transmission system. That allows the axle counter sensors to be located a significant distance from the evaluator, and is useful when using centralised interlocking equipment, but less so when signalling equipment is situated beside the line in equipment cabinets.